Mascara formulations are determined of two main sorts: water based and organic- solvent based. Both types can supply smooth and homogenous applications on eye- lashes. Additionally, a very important component of mascaras is that formulations require to be matched with applicator brushes.

Mascara’s ingredients commonly consist of a carbon black or iron oxide pigment to darken lashes; a polymer to form a film that coats lashes; a preservative; and thickening waxes or oils such as lanolin, mineral oil, paraffin, petrolatum, castor oil, carnauba wax, and candelilla wax.

What solvent is used in mascara?

Whether in an anhydrous or emulsion form, waterproof mascaras commonly consist of a unstable organic solvent as the main element. Isododecane is mainly selected for these formulas, but also hydrogenated polyisobutene for Asian formulas in particular.

Mascara is one of the number one beauty products used by ladies. However before you layer on the thick lashes, check what may be lurking in your preferred mascara. How safe is your mascara?

Many of us don’t suppose twice before we put on our favorite mascara. We have been doing it when we can consider we are able to recollect. It’s simply part of what we do. It makes our eyes look brighter. Our eyes stand out greater with our long, lush lashes. It makes us feel excellent to look good.

Making Waterproof Mascara and why Homemade Mascara that Doesn’t Smudge?

Making your personal makeup isn’t as difficult as it seems. In reality, a lot of makeups share the same ingredients, which include eyeliner and mascara, so that you might as properly make both.

Some of the ingredients in homemade makeup would possibly marvel you and most likely, you already have a number of them on hand. I realize once I began making things such things as foundation, setting powder and dry shampoo, I was shocked to find myself gathering ingredients from my pantry.

I like that I make my own makeup at home with all-natural ingredients. So I am excited to share with you my most up-to-date endeavor, mascara!

The added beeswax in this recipe will assist to make this mascara waterproof. Beeswax has a natural protective substance known as propolis. Propolis has antibacterial, antifungal, and antiviral properties that can produce healthy lashes.

I prefer to use beeswax pellets to make measuring small quantities less difficult. If you don’t have pellets, you may shred a few beeswax off of a bar to get the amount needed for this recipe.

What is Mascara Made of?

For as long as I can remember, I have heard mascara has been made with bat feces. I guess I never truly believed it, or at least tried to notify myself it wasn’t true.

Mascara contains a colorant guanine, which may be observed in bat feces, however for mascara, it is far actually derived from fish scales. But, there are still many other substances found in mascara that I would alternatively no longer not put on my body. I would much prefer to make my own to avoid such substances.

To make your own mascara, you will need:

Activated charcoal

Bentonite clay

Vegetable glycerin

Aloe Vera gel

Beeswax

Essential oils, optional

Empty mascara tube

Homemade Mascara Recipe Ingredients

1/2 teaspoon activated charcoal; you may need to adjust depending on color preference.

1/2 teaspoon bentonite clay.

1/2 teaspoon glycerin.

1/4 teaspoon pure aloe Vera gel.

1/8 teaspoon beeswax.

2 drops rosemary essential oil.

2 drops lavender essential oil.

Instructions

- Add all of the components, besides the essential oils, to a small saucepan.

- Heat over medium warmness till the beeswax is melted.

- Stir in essential oils. You need a very smooth texture and can add in extra glycerin if needed.

- Pour into an empty mascara tube.

Proper Essential Oils for Mascara

You don’t have to add in essential oils, but they do have a few great advantages for the lashes. Rosemary and lavender essential oil can thicken, strengthen and help with hair growth.

Make your own eyelash serum with castor oil, rosemary oil, and lavender oil. Or you could simply add the essential oils into your mascara to get the similar outcomes even as wearing makeup.

in case you are analyzing this post but have zero favored to make your personal mascara, you could add some drops of the essential oils given below into your store-bought mascara to aid your eyelashes development.

Other essential oils to test:

- Cedar wood

- Sandalwood

- Frankincense

- Tea tree or melaleuca

NOTE: Essential oils should not get in the eye and should be flushed out with water if they do. Be cautious whilst applying your mascara to ensure the oils do not get in the eyes.

What are polymers in mascara?

One generally used polymer in mascara is polyvinylpyrrolidone (PVP). Polymers are added to mascaras to create a film to encapsulate each separate lash. Some polymers are able to perform this due to their binding and film forming properties. Polymers create a film around eyelashes because of their transport properties.

Mascaras formulation

The formulation of mascaras has been a totally active subject over during the last two decades as formulations are requested to improve very distinctive elements of eye lashes: coloration, physical characteristics inclusive of curling and thickening, and daily wear resistance such as water and sweat resistance. These results can be almost instantly experienced and judged with the aid of the consumer, since mascara has an immediate impact on visual notion. One should also hold in thoughts when formulating, that mascara formulations need to be adjusted to the applicator utilized in a final product, especially in terms of viscosity and application fluidity versus solvent evaporation.

Mascara formulations are discovered of two fundamental types: water primarily based and organic- solvent based. Both kinds can give smooth and homogenous applications on eye- lashes. Additionally, a completely important aspect of mascaras is that formulations require to be matched with applicator brushes. This point is illustrated by the numerous patents existing on mascara applicator brushes.

a. Basic Formulation

A general combination breakdown of mascaras is given in Table 1 as a base of discussion to follow.

Table 1 Common mascara ingredients and ranges of typically used concentrations

Ingredient | Concentration | Examples |

Color | 1-12% | iron oxide, mica pigments |

Emulsifier | 3-10% | myristoyl, penta/hexapeptides |

Emollients | 25-50% | oils (jojoba, wheat, argan) |

Texture modifiers | 5-20% | hydroxycelluose, waxes |

Preservative | 0-1.5% | phenoxyethanol, propylparaben |

Film formers | 1-8% | silicones, dimethicone |

Solvent | Q.S | water, petroleum distillates |

Purposes of mascara

The number one purpose of a mascara is to present visual influence of long dark eyelashes to enhance the beauty of the eye area. Therefore, a first component might be the shade pigments. For a best assessment of the visibility of eyelashes against the background skin and eye, black is the most common primary pigment and is given by black iron oxide particles. Titanium dioxide is often added to disperse black pigments and give a deeper black concept the main coloration can be modified as a mass-tone coloration via addition of light-absorption pigments including browns, reds, and blue pigments (e.g., mica-based pigments). Two forms of light-effect pigments can be used: light-absorbing (dye pigments) and light- reflecting/interfering (multicoated interference pigments). The second one type is typically used in mascaras for its greater perception because of selective coloration of light being reflected however due to the lower toxicity of mica and its outer coating whilst in touch with eyelid skin and the humid mucosal membrane hosting lash roots.

Mascara structure

Stronger mascara hues are also present on the market and represent a smaller fraction of purchaser makes use of. Emulsifiers are then introduced to create a stable dispersion of these pigments.

Thickeners which includes hydroxyethyl cellulose serve to thicken this suspension and can add volume to the mascara coating applied to the eyelash. They have got a wide compatibility with most formulation bases, and while being usually used, additionally they increase viscosity so that the system desires to be a little more fluidized (e.g., oils or emollients) for a smooth flow of mascara utility.

Oils are commonly present to bring both better adhesion on the keratin of the lash keratin surface however to fluidize the formula to regularize flow and homogeneity at some point of utility. Oils additionally bring nourishment to the lash fiber by slightly penetrating into its cortex. Thickeners, such as waxes, have an opposite effect on the system by increasing viscosity but also result a slight solidification of the mascara film pending drying on eyelashes as the solvent evaporates. Because of this, it is generally suggested to move the applicator brush up and down in mascara tubes prior to use. The impact is to coat the locality, refluidize the formula, and have a fresh layer of formula on the brush while used. The same is suggested when using mascara consecutively.

b. Advanced ingredients

Specialty ingredients can be included to provide a better texture or regularity when applied with a brush as well as extra benefits: adhesion promoters, formulation stabilizers, thickeners, polymers, color pigments, active ingredients, and fragrance. Those substances are more and more frequently added to enhance the mascara film formation and stability on the eyelash and to bring new advantages to the final formula, consisting of water and wear resistance.

A detailed water-based mascara formulation is proven in Formula 1 below. This method has been shown to bring lash curling and water resistance but also a modest increase in lash thickness (volumizing effect).

Formula 1. Volume curling mascara with high water resistance

Phase | Ingredients | % (wt) |

A | D.I WATER | 45.42 |

B | Water | 10 |

C | Water | 10 |

D | Glyceyl stearate and Laureth-23 (CERASYNT 945) | 3 |

E | Triethanolamine (TEA 99%) | 1 |

F | Water | 5 |

G | Phenoxyethanol, octanediol (optiphen) | 1.5 |

Total: | 100 |

Procedure

- Pre-weigh water and disodium EDTA and mix until clear; add TEA and mix until clear. Sprinkle Ultrathix slowly until all in.

- Transfer to homemaker and slowly add xantham gum.

- Premix components of phase B and add to phase A; start heating to 75–80°C

- Weigh components of phase C and pulverize the usage of blender for about five minutes. Then, add to previous mixture and continue homogenizing.

- One at a time, add components of phase D and warmth to 75–80°C whilst blending.

- Add phase D to levels ABC whilst homogenizing for about ten minutes.

- Add TEA (phase E) and preserve homogenizing for ten minutes. Start cooling the mixture to 55°C.

- Switch to sweep agitation. Add phases F and G and cool to 25–30°C.

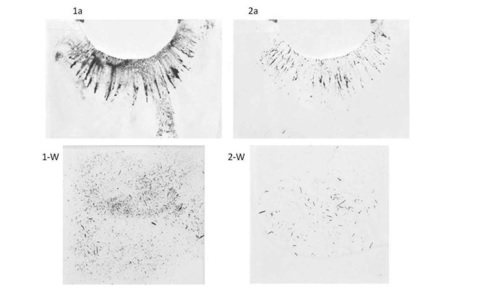

Properties

Adhesion promoters inclusive of silicones enhance film compatibility of the mascara with the keratin of the eyelash cuticles. Adhesives assist to prevent mascara flaking under daily stresses such as finger contact or bending or inter-eyelash friction. Stabilizers are used as homogenizers in the mascara. Thickeners such as hydroxyl celluloses offer richer coating applications on the lash and can thus bring volumizing properties to the completed product. Mechanical benefits such as anti-flaking or water resistance can be given to a formulation via polymers. They provide two advantages to the mascara film applied on the eyelash: trapping of dyes and global film integrity. They maintain the mascara dye particles by forming a three-dimensional network around them and throughout the film and thus prevent their release while lashes are available with waterous media like tears. Further, polymers give film integrity to the mascara even as nonetheless adapting to the bending stress of eyelashes during daily activities. This prevents mascara breakage with probability of dye leakage or potential flaking of the film.

Figure 1. Effect of 1% acrylate/C12–C22 alkyl methacrylate copolymer on water resistance: Test 1 (Top): Bending under wet conditions and Test 2 (Bottom):