Mascara is a beauty applied to the eyelashes to make the lashes thicker, longer, and darker. It is one of the most historical cosmetics recognized, having been utilized in Egypt in all likelihood as early as 4000 B.C. Egyptians used a substance called kohl to darken their lashes, eyebrows, and eyelids. The Babylonians and ancient Greeks also used black eye cosmetics, as did the later Romans. Cosmetics of all sorts fell out of use in Europe after the fall of Rome, though eye cosmetics persevered to be critical in the Arab world. Using cosmetics become revived in Europe at some point of the Renaissance.

There are 8 Unsafe Ingredients to Avoid in Mascara as follows

- Parabens. Parabens are dangerous preservatives which can be added to beauty merchandise to increase their shelf life. …

- Propylene Glycol. …

- Retinyl Acetate (Vitamin A Acetate) …

- Aluminum Powder. …

- Coal Tar Dyes. …

- Fragrance. …

- Formaldehyde Releasing Preservatives. …

- BHT and BHA.

There are techniques of making Mascara, anhydrous and emulsion approaches. In the anhydrous approach, waxes, oils, and pigments are combined in a blending tank, heated, and stirred using a propeller blade.

In the emulsion type of the mascara manufacturing technique, the water and thickeners are blended together, while the waxes and emulsifiers are heated in a separate container where the pigment is then added. A homogenizer mixes each of those combinations to interrupt down the oils and waxes and maintain them in suspension in the water. Mixing continues till the combination becomes the dark paste we all die for.

A good mascara and how we can choose a Safe Mascara

Upon utility, a great mascara won’t clump, feel crunchy or dry, or make your eyelashes stick together. It should additionally distinctly do what it claims it going to do on the packaging, whether or not it is lifting, lengthening, volumizing, or curling your lashes.

Essentially you need to find a products that is safe and is not always toxic. The best way to check the protection of your current mascara is to check out the EWG’s Skin Deep Database. You can type in your brand and see how it rates for safety. You could also search for individual elements in your mascara to see how safe it is.

In case your favorite mascara rates between a 1 and 2, you know you have a nice, safe brand. Ratings of 3 to 5 are taken into consideration so-so. You may take into account switching to a safer brand when you run out. Anything above a 5 is considered dangerous and should probably be avoided.

I’m not one to repair something if it’s not broken. If you have a terrific brand that you love and it’s rated safe, stick with it. If your current brand is much less than clean, you could want to consider attempting a safer brand.

What does glycerin do in mascara?

Glycerin is utilized in cosmetics and personal care merchandise particularly to improve skin’s smoothness and moisture content (Wiki). It has humectant (draws moisture to the pores and skin), naturally emollient, and has a cooling effect on skin.

Glycerin

Glycerin is a colorless, odorless, viscous liquid which freezes to a gummy paste and has an excessive boiling point. Glycerin can be dissolved into water or alcohol, however not oils. Then again, many things will dissolve into glycerin without difficulty, simpler than they do into water or alcohol, so it is a good solvent.

Glycerin is used in cosmetics and personal care products mainly to improve skin’s smoothness and moisture content (Wiki). It is a humectant (attracts moisture to the skin), naturally emollient, and has a cooling effect on skin.

Origin: Glycerin (also called glycerol) is a naturally achieving alcohol compound and a component of many lipids. Glycerin may be of animal or vegetable foundation (EWG).

Products Found In: Facial moisturizer, body lotion, sunscreen, makeup, hair care, facial treatments, shaving cream, soap, water-based private lubricants.

Alternative Names: Glycerol, Glycerolum, Glicerol, Glyzerin, 1,2,3-Propantriol, Glycerinester, Pfl. Glycerin, Clycerin, Vegetable Glycerin (Cosmetic Analysis).

Toxicity: Glycerin (Glycerol or Glycerine) is typically classified as having low toxicity (EWG).

Can mascara cause dry eyes?

Eyeliner, mascara, and different merchandise can result to or worsen your dry eye. They can clog the meibomian glands in your eyelids, which make the oil on your tears. This is specifically possibly in case you use eye makeup that includes glitter, of if you apply eyeliner to the inside of your lash line.

How many sorts of mascara are there?

There are six main types of mascara formulated to obtain specific eye-popping results. Find the proper mascara for you, whether you are seeking out lengthy luscious lashes or vivacious volume.

Can you use Vaseline as mascara?

Apply a light layer of Vaseline to your upper and lower lashes just like you would utilize your mascara. (Be cautious to avoid getting jelly to your eyes.) Why this works: Vaseline mimics the consequences of mascara, leaving you with lashes that look more thick, shiny and voluminous.

Making mascara, water proof and water resistant mascara

How can we make mascara?

- Put coconut oil, aloe Vera gel and grated beeswax in a small saucepan over low heat. Stir until the beeswax is absolutely melted

- Pour the combination into the mascara vessel

- Now keep in a refrigerator or cool place. …

- If you need extra hold to your mascara, add much more beeswax.

What is the pH of mascara?

The neutralizing system additionally influences the mascara’s pH, which ought to be within 7.5-8.5 since it is applied around the eye area.

What ingredient makes mascara water resistant?

Waxes and silicones are what make waterproof mascara more resilient against sweat, tears, and water. If you examine two tubes of mascara—one regular and one waterproof—you’ll be aware the latter incorporates some added ingredients, which includes isododecane and cyclopentasiloxane, that are not doing your lashes any favors.

How do you make regular mascara waterproof?

Mascara does not look fantastic whilst it is come into touch with water. Fortuitously waterproofing your mascara is highly easy, it can be completed by using spraying hairspray over the mascara once applied, by way of blending hairspray and mascara prior to application or by using a purpose-made waterproof top coat.

Water-resistant vs. waterproof mascara

Since mascara is applied to your lashes with a bristle brush, its degree of water-resistance might be a prominent issue for someone who would like to spend a day at the seashore. Water-resistant mascaras are oil-in-water emulsions and especially include waxes of natural and mineral foundation, which can face up to the penetration of water only to a certain degree. While, water-proof mascaras are water-in-oil emulsions, which contain water rebuffing components like isoparaffins, isododecane, or siloxanes. This acts as a shield against water which gives the desired resilience in opposition to sweat, tears, and even complete water submersion at the seaside!

mascara making

Industrial emulsifiers

An emulsifier is used to mix two immiscible liquids. Heating or cooling requirements all through emulsification, overpressure or vacuum necessities, the need for wall scrapers, design of the mixing head, the viscosity of the liquids, and the preferred droplet length are all critical considerations while selecting an emulsifying gadget. Emulsifiers are commonly used in the food industry for the manufacturing of batters, creams, and sauces, in the pharmaceutical and cosmetics industry for the production of creams and lotions, and within the chemical industry for the manufacturing of paint and other emulsions.

Filling lines

Industrial filling device solutions are used to package a measured mass or volume of a product, at the stop of a production line, into a packaging container suitable for the product. The choice of filling gadget or filling line relies upon the physical state of the product, the packaging container of desire, the favored mass or volume per container, the required manufacturing volume, and considerations of sterilization and protection.

Characteristics of mascara

Early mascara from the contemporary generation commonly took the form of a pressed cake. It became applied to the lashes with a wetted brush. The components typically were 50% soap and 50% black pigment. The pigment turned into sifted and mixed with soap chips, run through a mill several times, after which pressed into cakes. A variation on this was cream mascara, a lotion-like substance that become packaged in a tube. To use it, the person could squeeze a small amount of mascara out of the tube onto a small brush. This was a messy process that was much advanced with the invention in the 1960s of the mascara applicator. This patented tool was a grooved application rod that picked up a steady amount of mascara whilst pulled from the bottle. The grooved became quickly replaced with a brush. This new ease of application may also have contributed to the expanded reputation of mascara in the overdue 1960s.

Raw Materials

There are numerous special formulas for mascara. All contain pigments. In the United States, federal regulations limit using any pigments derived from coal or tar in eye cosmetics, so mascaras use natural colors and inorganic pigments. Carbon black is the black pigment in most mascara recipes, and iron oxides offer brown shades. Other colorings such as ultramarine blue are used in some formulation. One common type of mascara consists of an emulsion of oils, waxes, and water. In formulation for this kind of mascara, beeswax is regularly used, as is carnauba wax and paraffin. Oils may be mineral oil, lanolin, linseed oil, castor oil, oil of turpentine, eucalyptus oil, and even sesame oil. A few formulas comprise alcohol. Stearic acid is a not unusual ingredient of lotion-based formulation, as are stiffeners which include ceresin and gums such as gum tragacanth and methyl cellulose. Some mascaras consist of fine rayon fibers, which make the product more viscous.

The Manufacturing Process

There are primary sorts of mascara presently manufactured. One kind is called anhydrous, meaning it includes no water. The second type is made with a lotion base, and it is manufactured by means of the emulsion approach.

Anhydrous method

- 1 In this method, components are jumbled in tanks or kettles, which make a small batch of 10-30 gal (38-114 1). The substances are first cautiously measured and weighed. Then a worker empties them into

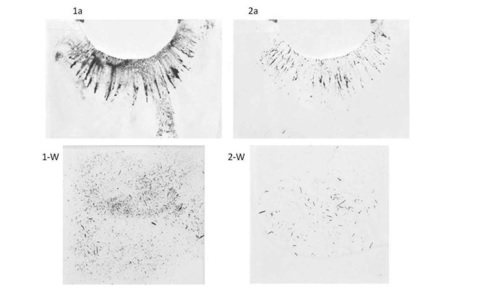

Mascara can be made in distinctive ways. In the anhydrous technique, all of the elements are blended, heated, and agitated. With the emulsion approach, water and thickeners are combined, whilst the waxes and emulsifiers are combined and heated one at a time. Pigments are added before both combinations are combined in a high- pace agitator called a homogenizer. The end result of both technique is a semi-solid substance that is ready to be packaged.

The combination tank. Heat is applied to melt the waxes, and the combination is agitated, typically via a propeller blade. The agitation maintains until the mixture reaches a semi-solid state.

Emulsion method

- 2 In this approach, water and thickeners are blended to make a lotion or cream base. Waxes and emulsifiers are heated and melted one after the other, and pigments are brought. Then the waxes and lotion base are mixed in a completely excessive velocity mixer or homogenizer. In contrast to the tank or kettle above, the homogenizer is enclosed and mixes the ingredients at excessive pace without incorporating any air or inflicting evaporation. The oils and waxes are broken down into very small beads via the fast action of the homogenizer and held in suspension in the water. The homogenizer may hold as little as 5 gal (19 1), or as much as 100 gal (380 1). The high-speed blending motion maintains until the mixture reaches room temperature.

The following steps are commonplace to both types of mascara.

Filling

- 3 After the mascara solution has cooled or reached the right state, employees switch it to a tote bin. Next, they roll the tote bin to the filling vicinity and empty the solution into a hopper on a filling gadget. The filling machine pumps a measured amount (typically around 0.175 oz [5 g]) of the solution into glass or plastic mascara bottles. The bottles are commonly capped by hand. Samples are eliminated for inspection, and the rest are readied for distribution.

Quality Control and future

Tests for quality and purity are taken at various levels inside the manufacture of mascara. The chemicals are checked in the tank earlier than the integration starts to make certain the right ingredients and proper quantities are in place. After the batch is blended, it is rechecked. After the batch is bottled, significant samples from the beginning, middle, and end of the batch are taken out. Those are examined for chemical composition. At this factor they are also tested for microbiological impurities.

Some mascaras on the market today boast all-natural ingredients, and their recipes vary little from products that could have been homemade at 100 years ago. One development that could affect mascara manufacturing in the future, however, is the improvement of recent pigments. Researchers in the plastics industry have advanced formidable, obvious pigments that have lately been introduced to lipsticks. Plastic-derived pigments may be of interest to mascara producers as nicely.