Lipstick; history, components and oils used in its production

Lipstick in some shape or form has been around for a long time and has usually been a part of the fashion statement. Records tells us that ancient Egyptians used henna to color their lips. In line with Meg Cohen Ragas and Karen Kozlowski in their book, “Read My Lips: A Cultural History of Lipstick,” a reddish purple mercuric plant dye called fucusalgin, 0.01% iodine, and some bromine mannite–was used for lip rouge. Little did the ancient Egyptians know that it became probably toxic — communicate about the kiss of death!

Lipstick contains a diffusion of waxes, oils, pigments, and emollients. The wax gives lipstick its form and ease of application. Among the waxes are beeswax, a substance obtained from bee honeycombs that includes esters of straight-chain monohydric alcohols with even-numbered carbon chains from C24 to C36 and direct -chain acids additionally having even numbers of carbon atoms up to C36. Different waxes consist of carnauba wax, that is an exudate from the pores of leaves of Brazilian wax palm trees, and candelilla wax, that is obtained from the candelilla plant and is produced in Mexico by immersing the plants in boiling water containing sulfuric acid and skimming off the wax that rises to the surface.

The oils and fats used in lipstick include olive oil, mineral oil, castor oil, cocoa butter, lanolin, and petrolatum. Greater than 50% of lipsticks synthetic in the U.S. include great quantities of castor oil. It forms a tough, shiny film when it dries after utility. However, ingestion of massive quantities of castor oil may additionally cause frequent rest-room visits.

Properties of ingredients in lipsticks

In current years, ingredients including moisturizers, vitamin E, Aloe Vera, collagen, amino acids, and sunscreen have been added to lipstick. The greater components preserve lips soft, moist, and protected from the elements.

Lipstick gets its color from a diffusion of added pigments. Among them are bromo acid, D&C Red No. 21, and related dyes. Other commonplace lipstick dyes are D&C Red No. 27 and insoluble dyes known as lakes, such as D&C Red No. 34, Calcium Lake, and D&C Orange No. 17. Pink shades are made by blending titanium dioxide with various shades of crimson.

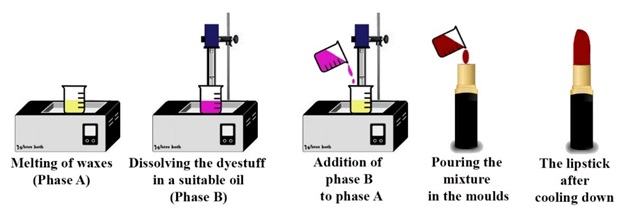

Making lipstick is similar to making crayons–a lot of heating and combining and stirring goes on. Simply put, the mixture is finely ground, and the waxes are added for texture and to preserve stiffness. Oils and lanolin are added for precise formula requirements. The hot liquid is then poured into cold metal molds in which it solidifies and is similarly chilled. The formed lipstick is put through a flame for about half a second to create a clean and glossy finish and to get rid of imperfections.

Some Lipstick combos

From the oven to the shop comes a diffusion of lipsticks: frosted, mattes, sheers, stains, and long-lasting color. Frosted lipsticks include a pearlizing agent– regularly a bismuth compound–that provides luster to the color. Bismuth oxychloride, that’s synthetic pearl, imparts a frost or shine. Bismuth sub carbonate is used as a skin defensive. Most bismuth combos used in cosmetics have low toxicity while ingested, however they will purpose allergic reactions whilst applied to skin.

Matte lipsticks are heavy in wax and pigment but lighter in emollients. They have more texture than shine. Cremes are a balance of shine and texture. Glosses have a high shine and low color. Sheers and stains include a lot of oil and a medium quantity of wax with a tad of color. Shimmers have greater glimmer, which comes from mica or silica particles. Long-lasting coloration lipsticks comprise silicone oil, which seals the color to your lips. Lip gloss normally comes in jars and includes one-of-a-kind proportions of the identical elements as lipstick but normally has less wax and more oil to make the lips shinier.

Lipstick Manufacture

Lipsticks are generally manufactured in small batches. A regular manufacturing technique might be as follows: The oil is heated in the process vessel to 175 – 185ºF (80 – 85ºC). The waxes are melted separately in a hemispherical jacketed vessel (frequently known as a “kettle”) typically outfitted with an anchor stirrer/scraper.

Lipsticks encompass pigment dispersed into a mixture of oils and waxes. The range of pigments and different raw materials accepted to be used is strictly limited by regulatory government including the EU and FDA. Oils used consist of castor oil, mineral oil or petrolatum; waxes include beeswax, carnauba, candelilla and ozokerite (ceresin). Waxes can be utilized in either powder, flake, prill pellet or solid form. Silicone compounds are also sometimes used in the base formula. Other components encompass emolients, pigment dispersants, preservatives and fragrances. Some products also comprise additional properties which include UV protection or pearlescent finish. Typical ratio of oil: wax: pigment would be as follows:

- Oil: 50 – 70%

- Wax: 20 – 30%

- Pigment: 5 – 15%

Lip salves (or balms) are formulated from a comparable base, but instead of pigments they include extra moisturizers, sunscreen agents or “active” ingredients which includes camphor.

Most lipsticks are made from three basic substances: wax, oil, and pigment. Pigment is the color. Waxes provide form and a spreadable texture. Oils — like petrolatum, lanolin, cocoa butter, jojoba, castor, and mineral — add moisture.

The Process

Lipsticks are typically manufactured in small batches. A typical manufacturing method would be as follows:

- The oil is heated in the process vessel to 175 – 185ºF (80 – 85ºC). The waxes are melted one after the other in a hemispherical jacketed vessel (regularly known as a “kettle”) generally outfitted with an anchor stirrer/scraper. Part of the oil may be added to the kettle to aid the process.

- The wax phase is added to the oil phase. Diverse sorts of mixers/dispersers are used to mix the two phases.

- A “pigment grind” is ready by dispersing the powdered pigment into part of the oil using a triple roll mill, bead mill or comparable conventional mill. More and more premicronized pigments are used. Those do not require grinding as such but some degree of shear may be required to break down any agglomerated particles.

- Ready-to-use liquid pigment dispersions are also extensively used despite the incremented cost. Those can be added directly to the oils and waxes without pre-processing.

- The pigment grind is added to the oil/wax phase and blended until a homogeneous product has been performed. This could require passing via a colloid mill or comparable.

- The combination is cooled barely earlier than fragrances, preservatives and other ingredients are added.

- The completed product is held at a lower temperature earlier than being poured into molds and cooled to solidify.

- The sticks may be “flamed” to provide a glossy finish to the surface.

What chemicals are in lipstick?

The ingredients in lipstick include a number of toxic chemicals such as:

- Methylparaben. Methylparaben is added to lipstick because it is an antifungal and a preservative. …

- Polyparaben. …

- Retinyl Palmitate. …

- Dyes. …

- Tocopheryl Acetate

Lipstick emollients

- Lanolin.

- Castor oil.

- Bis-Diglyceryl Polyacyladipate-2 (synthetic Lanolin)

- Shea Butter.

- Polybutene.

- Hydrogenated Polyisobutene.

- Triisostearyl Citrate.

Step 1 – Melt the olive oil, coconut oil, and beeswax in a bowl and mix away. Step 2 – Add a few drops of red food coloring to this moisturizing mix. Use a stick or a toothpick to stir the mixture together. Step 3 – Pour the mixture in a container and leave it in the fridge to set.

Best Cosmetic Ingredients Used for Manufacturing Purposes

For the manufacturing of quality accredited Cosmetic Color products and lipsticks, there is a need for sufficient components. In all the required ingredients, color is the most important one. Well, we are here with a huge product list in the cosmetic market and we promise to use all the safe components for its manufacturing. For that reason, we are using ingredients which can be safe for manufacturing body care, skincare, hair care products. Moreover, we continually tests the quality of the ingredients to make certain the highest quality of the products.

We are a straightforward name in the domain of all the color products and lipsticks. Also, we are a team of professional experts serving in the beauty market. So, our perfectly blended color cosmetic merchandise and lipsticks are prepared with the best raw substances.

Organic Color Pigments for the Manufacturing and Exceptional Presence for Private Label

The natural pigments we use are made from carbon and other molecules. Lake Colors, Toners, and true pigments are the 3 major color classifications of natural pigments used for cosmetic products. So, Cosmetics is using only the certified range of raw pigments and substances for the manufacturing of coloration lipsticks and other products in this category. The colors of our natural pigments are much brighter than every other chemical-based or inorganic pigment.

Our company is working for years now and we’re now much more skilled in the field of cosmetic coloration products manufacturing primarily based on international requirements. All our experienced personnel members are working in one of a kind ranges for better manufacturing processes. The manufacturing unit at cosmetics has all nicely -designed machinery, equipment, and different necessities for bulk production. So, our manufacturing knowledge and international quality standard acceptance have made us a dependable source for coloration Cosmetics & Lipsticks.

Waxes in Lip Products

Did you understand wax is a common ingredient found in many beauty merchandise? Wax has many specific properties that could advantage lip product customers and manufacturers, from retaining moisture to holding the shape of products. Study the sorts and advantages of wax in your preferred lip products.

Waxes can assist lip products retain their function and quality. Many manufacturers encompass wax in their lip merchandise because they act as an emulsifier for ingredients. They prevent oils from keeping apart within the product and maintain other component substances together. Wax is crucial for keeping the form of lipsticks.

The texture of wax allows maintain lip products on your lips for longer. Wax assists maintain a thick sticky consistency so it doesn’t run or drip when wearing it, specifically with more liquid products like lip gloss. Overall, wax can offer a wide range of benefits to lip merchandise.

Vegans can pick from a variety of plant-based waxes. Carnauba is a popular choice for lip balms, which manufacturers can use to thicken and offer a glossy finish.

Lip Balm

Depending on the brand and type of lip balm, manufactures can use diverse waxes to create the product. Beeswax lip balm is famous because it is a natural honeybee product from their hives. It has several skin and lip care advantages, inclusive of working as a natural moisturizer for hydrated and soft lips. Due to the fact bees create it naturally, many prefer it because they understand it is all-natural with minimum additives, creating an extra organic product. After production, the wax sits in honeycombs, creating a sweet, natural scent.

Lanolin and paraffin are other popular waxes for lip balms because they could soften lips and moisturize. Because lip balms seek to offer comfort, hydration and care to lips, waxes can help add moisturizing elements to balms. In most lip balms, manufacturers can opt from many wax kinds and use a combination of waxes to create the final product. The presence of wax within lip products, mainly lip balms, facilitates them function better, making them best merchandise for protecting, softening and soothing chapped lips.

Lip Gloss

Lip gloss gets its shine from emollient oils, which soften and moisturize skin. Most formulation use lanolin derivatives or polybutene, a silicone-like hydrocarbon, to assist smooth and soften lips. Manufacturers depend upon waxes in lip glosses to provide them thickness and aid them stay in place on your lips. Ozocerite wax is a commonplace choice to add to the texture of lip gloss.

Due to the fact clients select lip gloss for its soft and nearly liquid texture, wax becomes crucial in making it. Manufacturers turn to wax to preserve a liquid consistency that remains on lips and best provides for their clients.